St Pats has sold 561 MEP corkers

P35, P45, P12, P55

|

|

MEP Corkers

- St. Patrick's is has been the EXCLUSIVE importer and authorized distributor of MEP in North America since 2003.

- MEP is a family business founded in 2002.

- All MEP machines are designed, engineered, constructed, and tested entirely in-house. This is what separates MEP.

- MEP corkers that appear elsewhere in North America came through an Italian distributor, and service and parts must come thru the Italian distributor.

We set up each corker and test prior to shipping. Please send your bottles and corks.

|

|

| Click Here for Corker Parts and Manuals |

|

|

|

|

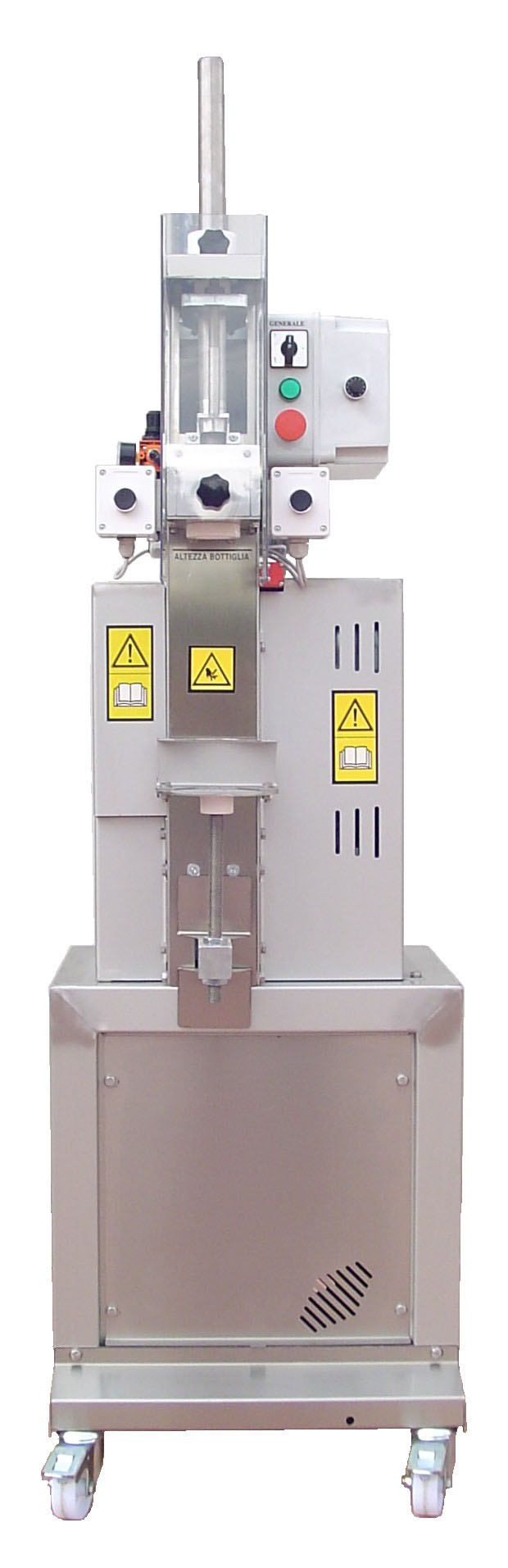

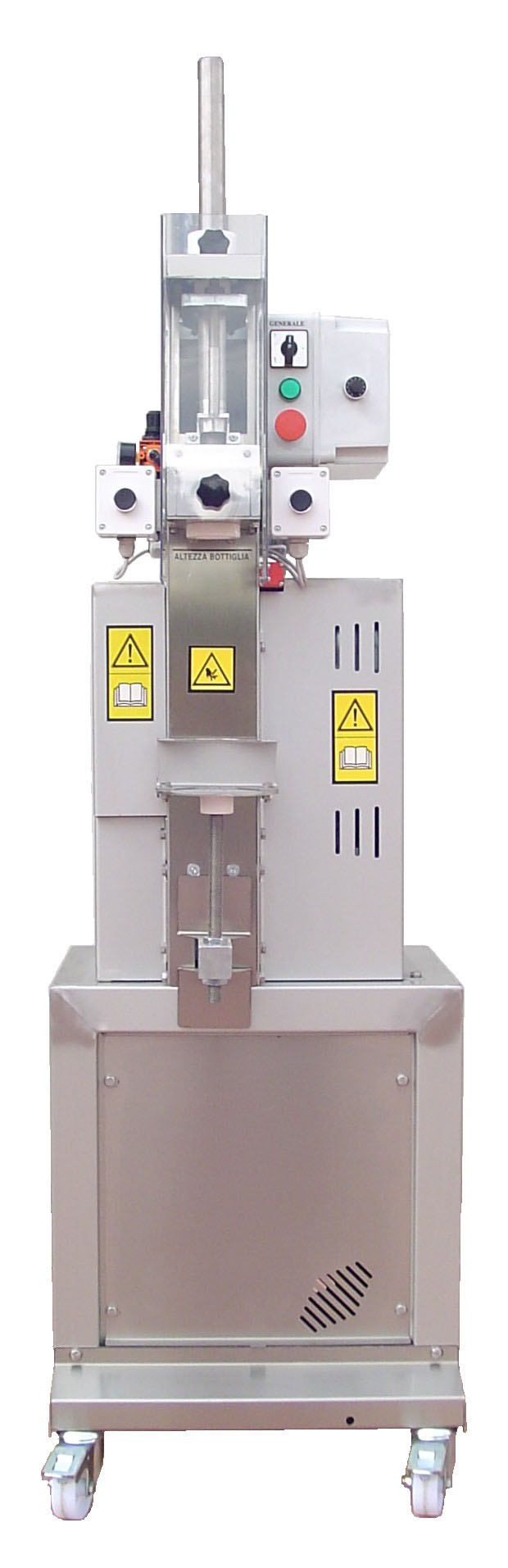

on base with wheels--photo not updated

|

|

|

Includes N2 regulator and tubing

on base with wheels--photo not updated

|

|

|

Includes CO2 regulator and tubing

on base with wheels--photo not updated

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P35 Electric Corker wtih Vacuum

- 800 bottles per hour

- Vacuum system

- Microswitch on bottle stand starts cycle

- ~650 cork hopper

- Stainless steel jaws

- Cork diameter 22-26 mm

- Bottle Height 9"-15"

- Corking time 1.8 seconds

- Floor unit on wheels 72" H x 21"W x 23" L

- 110 Volt, 60 Hz input, not GFIC (Frequency Drive)

- 304 stainless

|

P45 Electric Corker

Offered with gas or without

- 800 bottles per hour

- ~650 cork hopper

- Microswitch on bottle stand starts cycle

- Gas model supplied with N2 or CO2 regulator

- Stainless steel jaws

- Cork diameter 22-26 mm

- Bottle Height 9"-15"

- Corking time 1.8 seconds

- Floor unit on wheels 48"H x 21"W x 23"L

- 110 Volt, 60 Hz input, not GFIC (Frequency Drive)

- 304 stainless

|

|

|

P35 and P45 are supplied with a microswitch on the bottle stand.

|

|

|

|

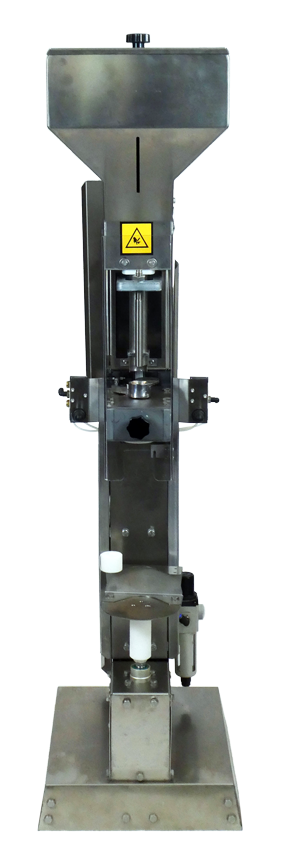

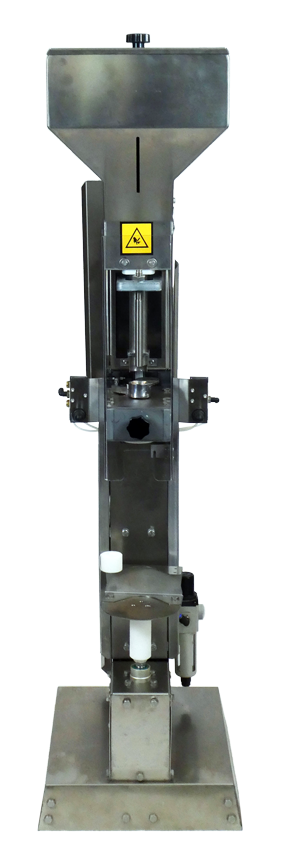

P12 Pneumatic Corker

- 600 bottles per hour

- ~650 cork hopper

- Push button operation

- Stainless steel jaws

- Cork diameter 22-26 mm

- Bottle Height 9"-15"

- Corking time 2.3 seconds

- Bench unit 55"H x 15"W x 19"L

- >5 SCFM compressor required (not included)

- 60-90 psi operational pressure

- 304 stainless

- Optional Stand with WHEELS

|

P45B Mushroom Corker for Belgian-style beer

- Cork must be same on both ends (not champagne cork). Usually 25.5 or 23.5 mm diameter.

- Insertion-depth of the cork is easily adjusted

- 700 bottles/hour

- ~650 cork hopper

- Push button operation

- Stainless steel jaws

- 29 mm diameter cork and smaller

- Bottles up to 15.3" H

- Corking time ~2 seconds

- Bench unit 48"H x 21"W x 23"L

- 110 Volt, 60 Hz input, not GFIC (Frequency Drive)

- Small compressor also required

- P45B can operate as a standard P45 wine corker.

- Optional Stand with WHEELS

|

|

|

P55 Champagne Corker

- 10-12 Corks manually fed into the tube

- Corking time: about 1,8 seconds

- 300-400 bottles/hour

- Suitable for Champagne corks and straight natural cork

- Champagne corks: 30,5mm diameter and height up to 50mm

- Straight natural corks: 26-30mm diameter and height up to 50mm

- Electric 230 V single phase, not GFIC

- Pneumatic---small compressor required

- Bottle Heights up to 14.75"

- Stainless steel jaws

- 304 stainless steel frame

|

CO2 vs N2 gas purge

The purpose of either vacuum or gas on a corker is to reduce the pressure under the cork. It is not to eliminate O2---there is an insignificant amount of air in the neck of the bottle---and air is only 20% O2. This is the single most misunderstood fact in bottling. However, sparging prior to filling the bottle is very important in reducing O2.

Vacuum reduces the pressure under the cork which mitigates any chance of cork working its way out of the bottle. CO2 purge will also reduce the pressure---because some of the CO2 will dissolve in the wine. It will not carbonate the wine---it is a trivial amount. N2 purge replaces most of the oxygen in the neck. However, N2 is less soluble in wine than O2 , so the pressure under the cork actually increases with N2 purge---although the pressure increase is also insignificant.

Nearly every supplier in the industry gets this wrong so we offer either N2 or CO2 regulator and let the client decide.